Asphalt concrete mixing plants can be divided into: mobile, semi-fixed and fixed according to the transportation mode (migration mode).

Mobile asphalt mixing plants include two types: drum type and intermittent type. We produce intermittent mobile asphalt mixing plants.

Mobile asphalt mixing plant is a device that mixes aggregate, asphalt and filler powder in the correct proportion to produce asphalt mixture. Compared with fixed asphalt mixing plants, its advantages are rapid disassembly, assembly and relocation, making it suitable for short-term small and medium-sized engineering projects.

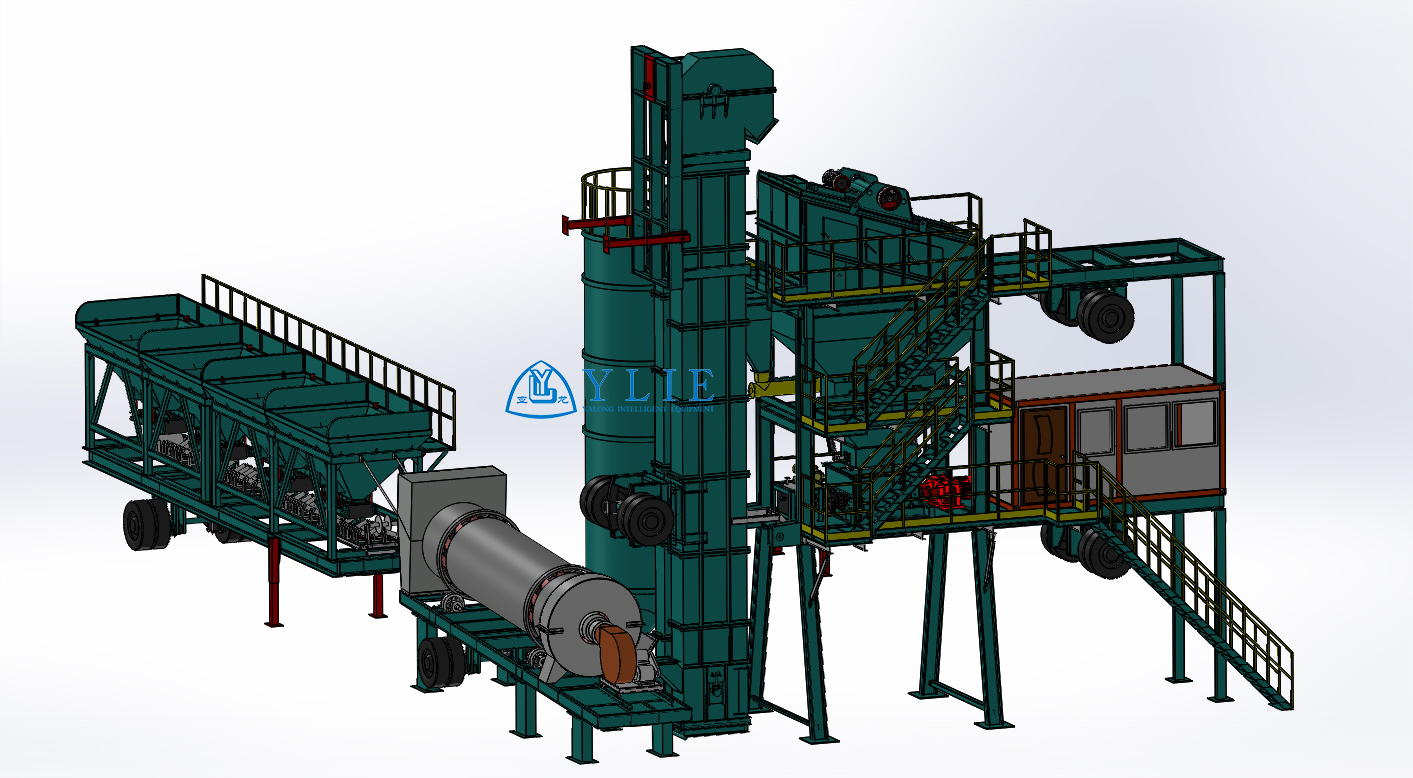

The mobile asphalt forced mixing plant consists of: cold aggregate supply system, drying system, mixing building, control system, and walking system. Compared with the fixed asphalt mixing plant, a walking system is added, making it easy to disassemble and assemble and quickly transition.

The mobile asphalt forced mixing station uses a forced mixer, which has the characteristics of batch mixing, precise screening, and accurate weighing, so that cold aggregate, asphalt, and fillers can be mixed evenly and fully to produce high-quality asphalt mixture.

-

-

Mobile Asphalt Mixing Plant120TPH

-

-

Mobile Asphalt Mixing Plant 80TPH

Application Scope of Mobile Asphalt Mixing Plant

1. County and township highway construction

Due to its widespread use in asphalt driveway repair, mobile asphalt equipment China is widely used in asphalt production for urban or rural road construction.

low grade road construction

Its silo and drum mixer are set on a wheeled chassis for transfer between different construction sites. This feature makes it very suitable for low-grade road asphalt paving or repair construction.

Other construction projects

Since our mobile asphalt plant is so convenient to use, it can be applied to other types of construction work.

Main Feature

1. The structure design of the mobile asphalt mixing plant has high mobility, small footprint, convenient transportation and less downtime.

2. The AVIC brand aviation plug is adopted, which is convenient to connect and quick to disassemble and assemble.

3. The production process is simple and convenient, and the control system is accurate, reliable and stable.

4. Fast moving speed and cost saving.

5. Fully automatic control of drying, weighing, mixing and discharging systems.

6. Each unit is separated from each other, and each unit can be seamlessly connected.